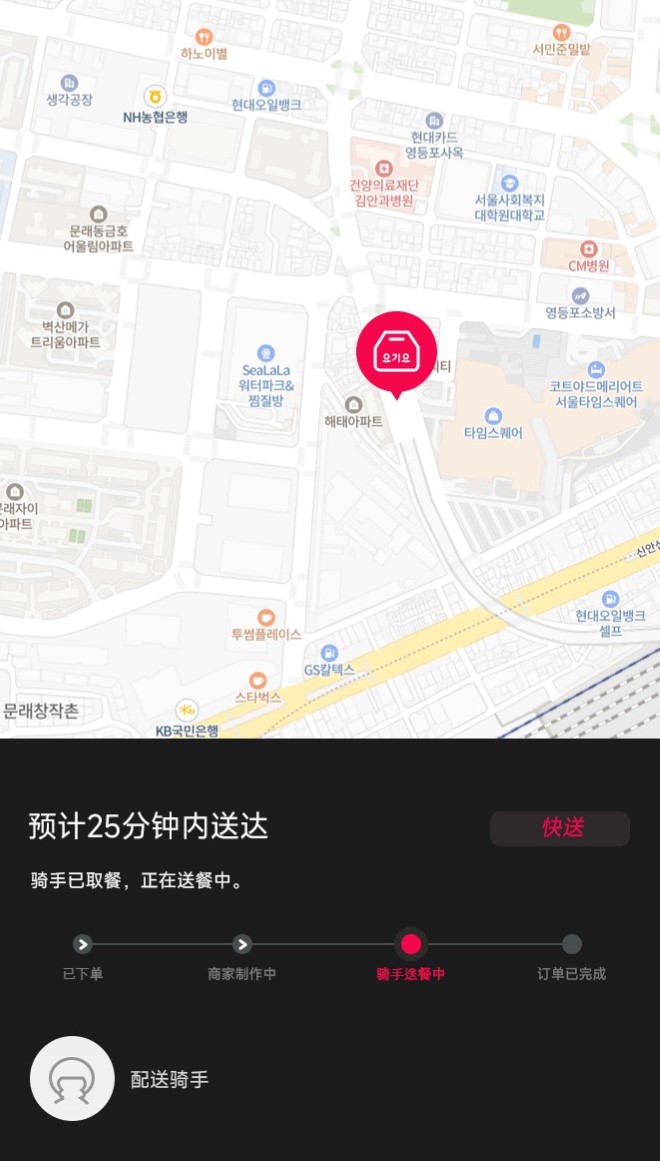

Before the rise of food delivery apps, issues like those mentioned were common in traditional food delivery services, a key logistics service in our daily lives. With the growing popularity of these apps, customers now receive real-time updates on their orders, including delivery status and estimated arrival time. Some restaurants even allow customers to track the entire process through the app, from cooking status to delivery initiation, the current location of the delivery rider, and confirmation of delivery completion.

Implementing "visualization" in daily logistics—whether within 20 or 90 minutes—enhances transparency and trust between customers and restaurants. It also boosts customer satisfaction, reduces uncertainties and customer service costs, and creates a win-win scenario for all parties involved.

In the global supply chain, new participants, increasingly complex processes, and unpredictable political, economic, and social factors emerge daily. Visualization enables logistics companies and other stakeholders to navigate these challenges and make quicker, more informed decisions. For logistics companies, it is crucial in maintaining the smooth flow of goods and services. In the modern logistics landscape, visualization is becoming a critical factor for success.

Ensuring logistics visibility

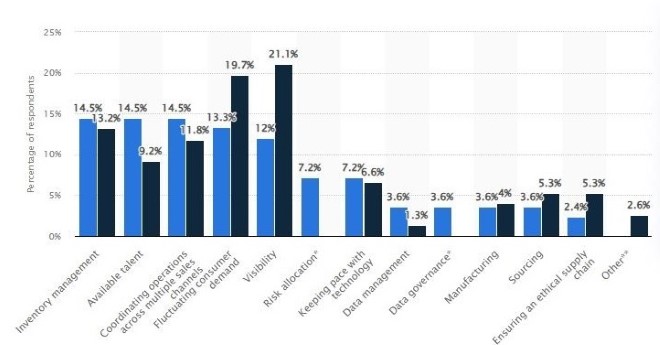

Enhancing visibility in the global supply chain is not a new concept. According to a 2018 Statista survey of global supply chain executives, the importance of visibility increased from 12% in 2017 to 21.1% in 2018, marking it as one of the most significant challenges in the logistics market.

To address these demands, large logistics companies are increasingly leveraging new technologies to enhance the visibility of modern supply chain management. Initially, barcodes, radio frequency identification technology (RFID), and GPS were employed, but more recently, advancements such as the Internet of Things (IoT), blockchain, big data, and artificial intelligence (AI) have come into play. Below are some of the technologies being actively utilized in this sector.

Internet of Things (IoT) Technology

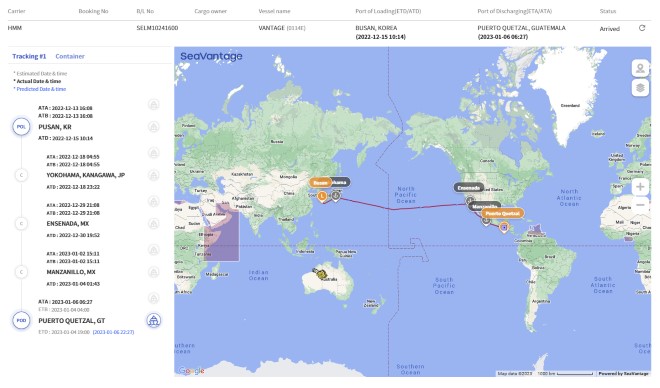

IoT technology is pivotal in improving the visibility of the logistics industry. By deploying IoT tags on trucks, pallets, containers, and other essential logistics items, participants can effortlessly monitor, track, and manage logistics operations by collecting and transmitting location, status, and environmental data in real time. For instance, logistics companies can attach IoT tags to products, trucks, and other assets to monitor location, speed, mileage, fuel consumption, driving routes, and performance data. Warehouses can utilize IoT sensors to monitor the real-time location, condition, and quantity of products. Moreover, IoT tags on equipment can help companies optimize workflow efficiency. Additionally, IoT sensors can be employed for real-time monitoring of potential hazards, including fire detection, intrusion alerts, and theft prevention.

For cold chain products that are sensitive to external conditions, IoT technology is particularly valuable. It enables continuous monitoring of temperature and humidity throughout all stages—from production to warehousing and up until delivery—ensuring any abnormalities are quickly identified.

Big Data and Artificial Intelligence (AI)

In the highly interconnected global supply chain, vast amounts of data are generated daily. This data is being increasingly collected, analyzed, and utilized to enhance visibility and improve overall efficiency.

For example, historical sales data, market trends, weather conditions, and other relevant information can be leveraged to predict inventory levels or demand for specific products in a given region. By integrating data from IoT sensors and GPS tracking with insights into road conditions, traffic, and customer demand, various factors can be analyzed and predicted in real-time. This allows for more accurate predictions of travel times, calculation of optimal transportation routes, and the redeployment of vehicles to minimize both transportation time and costs. Additionally, big data and artificial intelligence (AI) can be employed to forecast when logistics equipment and vehicles require maintenance or redeployment, enhancing responsiveness to potential emergencies, such as equipment failures.

Cloud Operating System

Before the advent of cloud-based operating systems, logistics companies faced significant challenges in sharing data with shippers, carriers, and other stakeholders. A cloud operating system not only securely stores logistics data but also enables all participants—including shippers and carriers—to view data in real time, collaborate more effectively, and make informed decisions quickly.

Large cloud service providers have established robust data security systems that help logistics companies minimize risks such as data loss, corruption, and tampering. These systems enhance trust in logistics visualization by offering flexible and scalable services that cater to a range of devices, operating systems, and applications.

Logistics companies are actively applying these technologies to enhance logistics visualization through various systems:

Transportation Management System (TMS)

The Transportation Management System (TMS) is a widely used visualization tool in the logistics industry. However, not all companies need to develop their own TMS to benefit from improved logistics visibility. TMS solutions provided by logistics companies enable participants to plan, execute, and monitor transportation activities effectively. These systems facilitate cargo loading and tracking, fleet management, route optimization, and carrier selection, simplifying transportation operations while boosting efficiency and reducing costs.

Warehouse Management System (WMS)

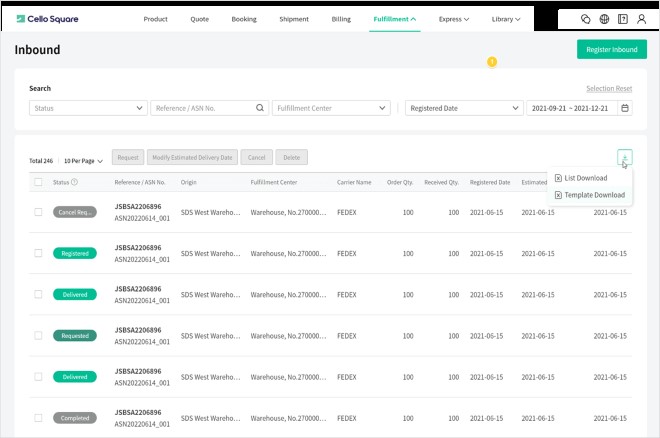

A Warehouse Management System (WMS) oversees the entire lifecycle of goods from their entry into a warehouse or distribution center to their shipment. With the explosive growth of e-commerce, there is a heightened demand for efficient distribution and real-time visibility. As a result, the importance of visualizing and responding to warehouse operations in real time has never been greater.

Integrating Systems for End-to-End Visibility

To achieve comprehensive "end-to-end supply chain" visibility, it is essential to seamlessly connect Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) systems.

Impact of Logistics Visualization on Customers and Consumers

Enhanced logistics visibility benefits not only logistics companies but also shippers and other supply chain participants. For shippers, accurate inventory data helps reduce excess stock and speeds up inventory turnover, leading to cost savings. Real-time monitoring and route optimization further cut transportation costs and boost overall efficiency.

Enhancing Customer Service Through Logistics Visibility

Logistics visibility significantly boosts customer service by keeping customers informed about their product's shipping status. This allows customers to adjust their schedules to align with the product's arrival time and prepare any necessary arrangements in advance. Additionally, if issues arise during transportation, companies can quickly address and communicate the reasons for any delays or damage, thereby building trust and improving customer satisfaction.

Furthermore, logistics visibility facilitates data sharing among shippers and all supply chain participants. This seamless collaboration helps prevent information discrepancies and enables joint problem-solving and planning. By predicting factors like weather and peak demand periods, companies can collectively devise strategies to reduce costs and enhance customer service. Visibility also helps in minimizing unexpected disruptions and lowering maintenance costs.

Shifting from JIT to JIC in the Global Supply Chain

The global supply chain has traditionally relied on Just-In-Time (JIT) production methods to maximize efficiency and minimize costs through precise demand forecasting. JIT enhances production flexibility and reduces inventory costs. However, this model is vulnerable to uncertainties like the COVID-19 pandemic and extreme weather events, which can lead to significant delays and disruptions. These challenges have highlighted the need for more resilient supply chain strategies.

In response, many companies are transitioning from JIT to Just-In-Case (JIC) strategies, supported by logistics visualization. JIC involves maintaining higher inventory levels to ensure stable production and supply amid uncertainties. This approach helps sustain high customer service levels during unforeseen events, boosting customer satisfaction and enhancing business confidence. Although JIC can lead to increased inventory costs and operational inefficiencies, logistics visualization plays a crucial role in managing real-time information, data analysis, and risk mitigation, enabling companies to navigate these challenges effectively.

Combining JIT and JIC for Future Supply Chain Success

Experts suggest that integrating the strengths of Just-In-Time (JIT) and Just-In-Case (JIC) strategies will be crucial for future supply chain management. Logistics visualization is expected to play a central role in this integration, allowing businesses to monitor product transportation, inventory status, and real-time supply chain conditions. This capability will enable shippers to make more agile decisions in the face of uncertainty, optimizing inventory management and production planning. As a result, companies can enhance customer satisfaction and maintain a competitive edge.

Enhancing Consumer Experience with Logistics Visualization

For consumers seeking swift and precise logistics services, logistics visualization offers the transparency needed to meet their expectations. With real-time tracking, consumers can know the expected delivery date and pinpoint the exact location of their orders. This visibility allows them to choose from various transportation methods and delivery notifications, personalizing their logistics experience.

Additionally, real-time inventory updates empower consumers to explore diverse options and products, offering greater convenience and choice. By providing accurate and timely information, logistics visualization enhances the overall consumer experience, making it easier to meet their needs and preferences.